Europe Electric Machines Repair Market 2025 Strengthening Motor and Generator Lifecycles

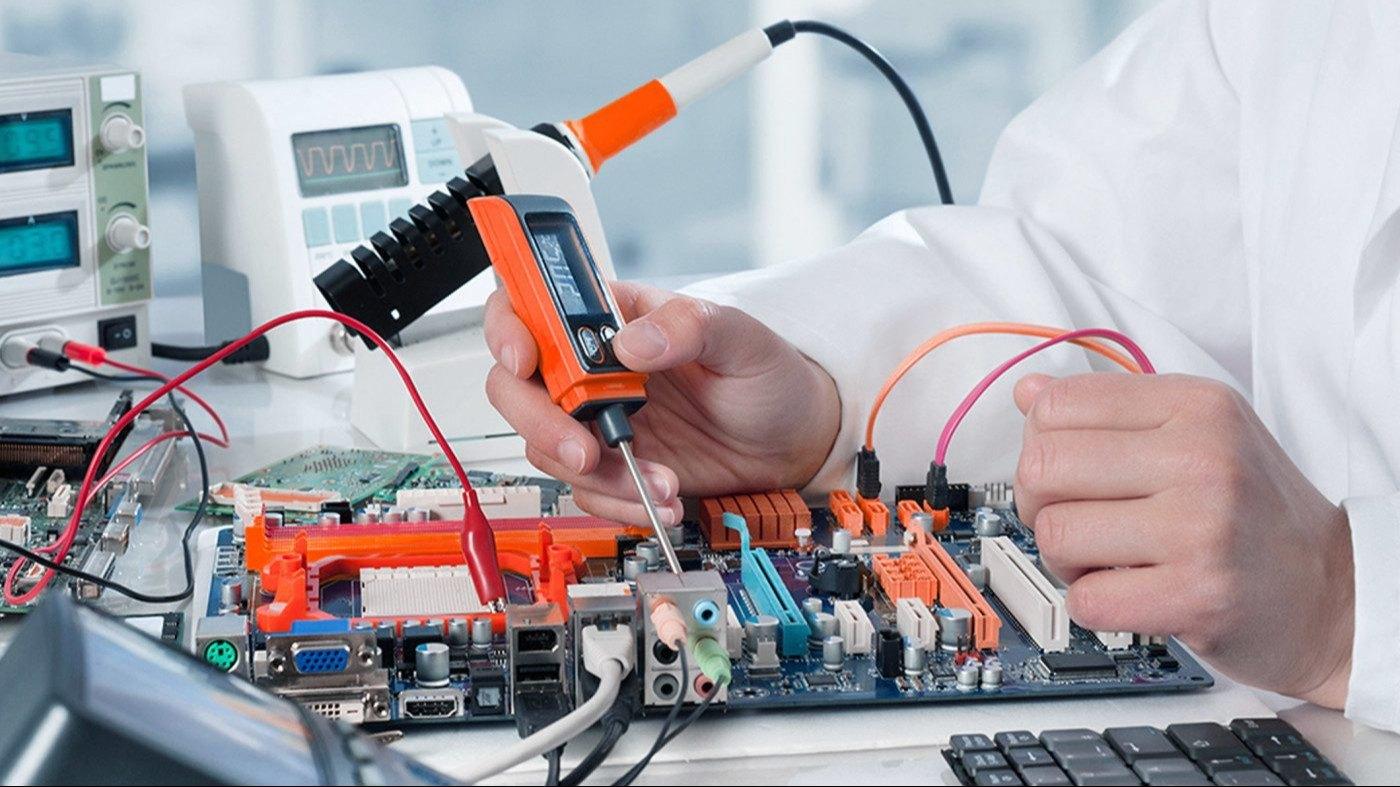

Across Europe’s factories, power plants, transport networks, and commercial facilities, electric machines quietly keep industries moving. Motors, generators, transformers, and rotating equipment form the backbone of modern industrial operations. While much attention is given to new equipment and advanced automation, an equally critical sector works behind the scenes to ensure reliability and continuity—the electric machines repair market.

As Europe continues to strengthen its industrial base and accelerate electrification across sectors, the demand for efficient, high-quality repair and maintenance services is steadily rising.

Market Outlook: Stable Growth Through 2035

The Europe electric machines repair market was valued at US$ 18,341.9 million in 2024 and is projected to reach US$ 23,729.7 million by 2035, expanding at a CAGR of 2.4% from 2025 to 2035. While growth is moderate compared to emerging technology markets, it reflects the sector’s maturity, resilience, and long-term importance.

Rather than rapid expansion, this market is defined by consistent demand driven by Europe’s vast installed base of electric machinery and the critical need to extend equipment life cycles.

Request Sample Research Report Copy from Here- https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86822

Industrialization and Manufacturing Activity Fueling Demand

One of the key drivers of market growth is rising industrialization and sustained manufacturing activity across Europe. Countries such as Germany, France, Italy, and the Nordic nations continue to invest heavily in advanced manufacturing, automotive production, heavy engineering, chemicals, and food processing.

These industries rely extensively on electric machines for production, material handling, and process control. As machinery operates under continuous or high-load conditions, wear and tear become inevitable. Repair services—including rewinding, refurbishment, alignment, and component replacement—help manufacturers minimize downtime and avoid costly equipment replacement.

In an environment where operational efficiency is critical, electric machine repair plays a vital role in maintaining productivity.

Growing Adoption of Electric Machinery Across Sectors

Another major growth driver is the expanding adoption of electric machinery across multiple sectors. Europe’s push toward energy efficiency, decarbonization, and electrification is increasing the use of electric motors and drives in industries such as transportation, utilities, construction, and renewable energy.

From electric rail systems and wind turbines to HVAC systems and industrial automation, electric machines are replacing traditional mechanical and hydraulic systems. As the installed base grows, so does the need for specialized repair and maintenance services capable of handling both legacy and modern equipment.

This trend is particularly strong in renewable energy and infrastructure projects, where reliability and uptime are mission-critical.

Repair Over Replacement: A Cost-Effective Strategy

In Europe’s highly cost-conscious industrial environment, repair is often preferred over replacement. New electric machines can involve high capital expenditure, long lead times, and complex installation processes. Repairing existing equipment offers a faster, more economical alternative.

Advanced repair techniques now allow service providers to restore machines to near-original performance levels. Precision balancing, thermal analysis, vibration diagnostics, and high-quality rewinding ensure repaired machines meet modern efficiency and safety standards.

This cost-effective approach is especially appealing to small and medium-sized enterprises (SMEs), which form the backbone of Europe’s manufacturing ecosystem.

Supporting Sustainability and Circular Economy Goals

Sustainability is a defining theme across European industries, and the electric machines repair market aligns closely with circular economy principles. Repairing and refurbishing equipment reduces material waste, conserves resources, and lowers the carbon footprint associated with manufacturing new machines.

By extending the service life of electric machinery, repair services support Europe’s environmental goals and regulatory frameworks focused on waste reduction and energy efficiency. As sustainability reporting becomes more stringent, repair and maintenance are increasingly viewed as strategic enablers rather than operational expenses.

Technological Evolution in Repair Services

The electric machines repair sector itself is evolving technologically. Service providers are adopting advanced diagnostic tools, digital monitoring systems, and predictive maintenance solutions to improve repair accuracy and turnaround times.

Condition-based monitoring enables early fault detection, allowing repairs to be scheduled before failures occur. This proactive approach reduces unplanned downtime and enhances equipment reliability—key priorities for industries operating in competitive global markets.

Additionally, repair specialists are expanding capabilities to service high-efficiency motors, variable frequency drive (VFD)-compatible machines, and equipment used in electrified mobility systems.

Skilled Workforce Remains Critical

Despite technological advancements, skilled labor remains at the heart of the electric machines repair market. Europe’s long tradition of engineering excellence provides a strong foundation, but workforce availability and skills development remain ongoing challenges.

Companies are investing in training programs to ensure technicians can service increasingly complex electric machines. Expertise in insulation systems, materials science, and digital diagnostics is becoming essential as machines grow more advanced.

Regional Strength and Market Stability

Europe’s electric machines repair market benefits from a dense industrial base, strong regulatory standards, and a well-established service network. Unlike markets driven by new installations, this sector thrives on long-term relationships, service quality, and technical expertise.

Demand remains resilient even during economic fluctuations, as critical machinery must be maintained regardless of market conditions. This stability makes the electric machines repair market a dependable segment within Europe’s broader industrial services landscape.

Looking Ahead: A Market Built on Reliability

As Europe continues to industrialize sustainably and expand electric machinery adoption, the importance of reliable repair and maintenance services will only increase. While new technologies and electrification trends reshape industries, existing machinery will remain in operation for decades—requiring expert care and refurbishment.

By 2035, the Europe electric machines repair market will continue to grow steadily, supported by industrial activity, electrification, and sustainability priorities. In an era focused on efficiency, resilience, and responsible resource use, electric machines repair stands as a quiet yet essential pillar of Europe’s industrial future.

- SEO

- Biografi

- Sanat

- Bilim

- Firma

- Teknoloji

- Eğitim

- Film

- Spor

- Yemek

- Oyun

- Botanik

- Sağlık

- Ev

- Finans

- Kariyer

- Tanıtım

- Diğer

- Eğlence

- Otomotiv

- E-Ticaret

- Spor

- Yazılım

- Haber

- Hobi