Planetary Roller Screw Market 2035 Enabling Heavy Load Linear Actuation

In modern industrial systems, performance is often defined by how accurately and reliably force can be controlled. From heavy-duty automation lines and aerospace actuators to electric injection molding machines and robotics, motion components must deliver extreme precision under intense loads. This is where planetary roller screws stand apart—offering unmatched load capacity, durability, and positioning accuracy in demanding environments.

As industries accelerate toward automation, electrification, and high-performance machinery, the planetary roller screw market is steadily gaining momentum worldwide.

Market Outlook: Stable and Sustained Growth Ahead

The global planetary roller screw market was valued at US$ 610.0 million in 2024 and is projected to reach US$ 1,105.0 million by 2035, expanding at a CAGR of 5.6% from 2025 to 2035. This growth reflects the increasing reliance on motion control systems that can operate under high loads while maintaining precision and long service life.

Unlike conventional ball screws, planetary roller screws are designed to handle significantly higher axial forces, making them a preferred solution in applications where performance and reliability are non-negotiable.

Request Sample Research Report Copy from Here- https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86826

Rising Demand for High Load and High Precision Performance

One of the key drivers shaping the planetary roller screw market is the growing demand for components that deliver high load capacity with exceptional precision, even in harsh operating conditions. Industrial machinery is becoming more compact, faster, and more powerful, placing increased stress on linear motion components.

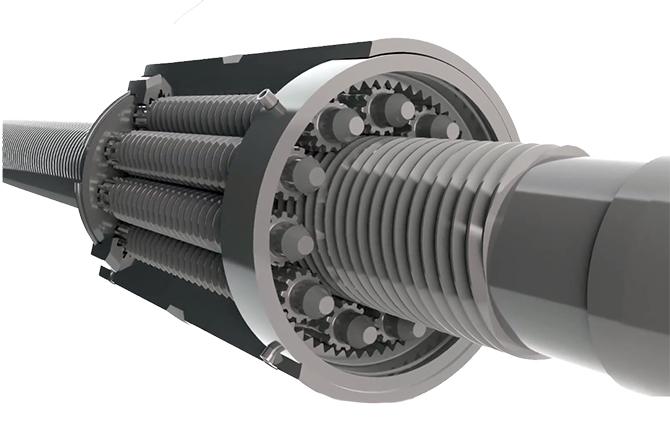

Planetary roller screws distribute loads across multiple threaded rollers, enabling smoother motion, higher rigidity, and superior fatigue resistance. This makes them ideal for applications such as servo presses, heavy-duty actuators, aerospace flight control systems, and industrial automation equipment where accuracy and repeatability are critical.

Operating Reliably in Harsh Environments

Harsh operating environments—characterized by high temperatures, vibrations, shock loads, and continuous duty cycles—are becoming more common across industries. Traditional motion components often struggle to maintain performance under such conditions.

Planetary roller screws are engineered for durability. Their robust design ensures minimal wear, reduced friction, and consistent performance even in extreme environments. This reliability is driving adoption in sectors such as defense, aerospace, oil & gas, and heavy manufacturing, where equipment failure can result in costly downtime or safety risks.

Industrial Automation and Electrification Trends Fueling Growth

The rapid evolution of industrial automation and electrification is another major catalyst for market growth. As factories transition from hydraulic and pneumatic systems to electric actuators, the demand for high-efficiency mechanical transmission components is rising sharply.

Planetary roller screws play a crucial role in converting rotary motion into precise linear motion in electrically driven systems. Their high efficiency and load-handling capability make them well-suited for electric presses, robotics, automated assembly lines, and material handling systems. As industries pursue energy efficiency, cleaner operations, and digital control, these screws are becoming a cornerstone of advanced motion systems.

Precision Meets Productivity

In addition to strength and durability, planetary roller screws deliver exceptional positioning accuracy. This precision directly translates into higher productivity, improved product quality, and reduced scrap rates in manufacturing processes.

In applications such as semiconductor equipment, aerospace component machining, and precision forming, even minor deviations can impact performance. Planetary roller screws enable consistent motion control, helping manufacturers meet tight tolerances while maintaining high throughput.

Customization and Application-Specific Design

One of the emerging trends in the planetary roller screw market is increased customization. Different industries require varying stroke lengths, load capacities, speeds, and environmental resistance levels. Manufacturers are responding by offering application-specific designs tailored to unique performance requirements.

This flexibility is expanding the addressable market and enabling adoption across a broader range of industries. From compact systems in robotics to large-scale industrial actuators, planetary roller screws are being engineered to fit increasingly diverse use cases.

Competitive Landscape: Engineering Excellence at the Core

The global planetary roller screw market is characterized by a mix of established motion control specialists and precision engineering companies. Competition is driven by product quality, engineering expertise, and the ability to deliver reliable solutions for mission-critical applications.

Some of the leading companies operating in the global market include ALT Rollerscrews, Bosch Rexroth Ltd., CHUAN HONG Precision Tool MFG. Co., Ltd., Creative Motion Control, LTK Lineartechnik Korb GmbH, Moog Inc., MTAR Technologies Ltd., NOOK Industries Inc., Power Jacks Limited, Rollvis SA, Schaeffler Group, Shanghai KGG Robots Co., Ltd., Tolomatic USA, and U-Screws Precision Co., among others.

These companies are investing in advanced manufacturing processes, material science, and precision machining to enhance performance and extend product life. Strategic partnerships with automation system integrators and OEMs are also helping expand market reach.

Supporting Sustainability and Energy Efficiency

While often overlooked, planetary roller screws contribute to sustainability by improving energy efficiency and reducing maintenance requirements. Their long service life minimizes replacement frequency, while high mechanical efficiency reduces energy losses in electric drive systems.

As industries prioritize sustainable manufacturing and lifecycle cost optimization, high-performance motion components like planetary roller screws are gaining preference.

Looking Ahead: Precision Driving the Future of Motion Control

As automation, electrification, and high-performance engineering continue to redefine industrial operations, the importance of robust and precise motion control will only grow. Planetary roller screws, with their unmatched load capacity, durability, and accuracy, are well-positioned to support this evolution.

By 2035, supported by expanding automation investments and demand for reliable performance in extreme conditions, the planetary roller screw market is set for steady growth. For industries pushing the boundaries of precision and power, planetary roller screws will remain a critical enabler of next-generation machinery and intelligent industrial systems.

- SEO

- Biografi

- Sanat

- Bilim

- Firma

- Teknoloji

- Eğitim

- Film

- Spor

- Yemek

- Oyun

- Botanik

- Sağlık

- Ev

- Finans

- Kariyer

- Tanıtım

- Diğer

- Eğlence

- Otomotiv

- E-Ticaret

- Spor

- Yazılım

- Haber

- Hobi