How to Prepare Digital Files for Smooth Embroidery Results

Embroidery looks calm and neat when it is done right. The stitches sit flat. The lines stay clean. The shape looks sharp. Many people think the machine does all the work. That is not true. Smooth embroidery starts long before the needle moves. It starts with the digital file.

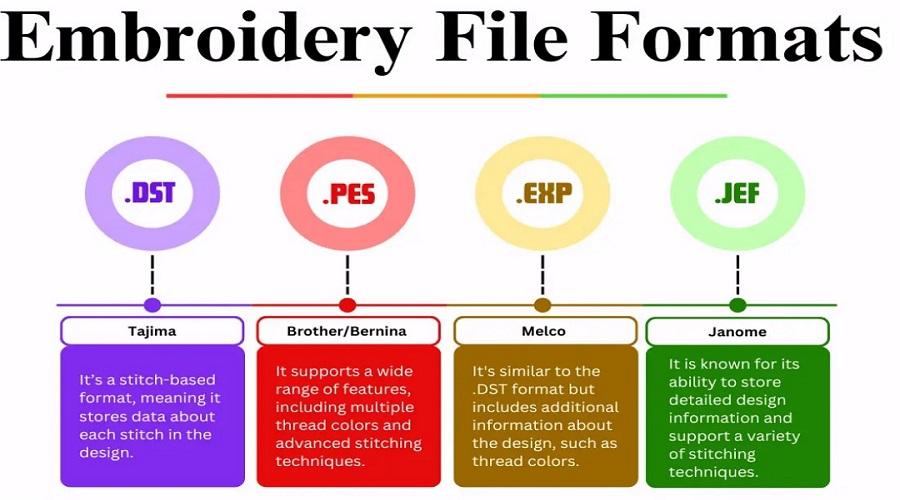

A strong result depends on the right Embroidery File Format and clean file setup. When the file is messy, the stitches become messy too. I have seen good artwork fail because the file was not ready. I have also seen simple art turn into perfect stitching with the right prep. The secret is careful planning before production.

I have worked with many embroidery files over the years. The same problems appear again and again. Files are rushed. Details are too small. Shapes are not cleaned. These small mistakes grow once the machine starts. That is why file prep is not optional. It is the base of quality work.

At Embroidery Digitizing Services in USA - Digitizing Buddy, file prep is treated as the first step of craftsmanship. We slow down at the start. This saves time later. Clean prep protects fabric, thread, and brand image.

Why Digital File Prep Matters

A machine does not think like a human. It follows instructions only.

If the instructions are weak, the result is weak. If the instructions are clear, the stitches behave well.

Good prep controls:

-

Stitch flow

-

Shape balance

-

Thread tension

-

Fabric stress

Each part works together. Remove one piece and quality drops.

Understanding How Embroidery Machines Read Files

Embroidery machines read numbers, not pictures.

A design on a screen looks smooth. A machine sees a map of points. Each point tells the needle where to move. This map must be clean.

Machines Follow Exact Paths

Every stitch has a path. The needle jumps based on that path.

Bad paths cause:

-

Thread breaks

-

Tangled stitches

-

Rough edges

Clean paths create smooth motion.

Digital Art Is Not Stitch Art

A logo made for print cannot be stitched as is. It must be rebuilt for thread.

Thread has weight. Ink does not. Thread pulls fabric. Ink does not.

This is why file prep is a special skill.

Cleaning Artwork Before Conversion

Most artwork needs editing before it becomes embroidery ready.

Removing Tiny Details

Very small parts do not stitch well.

Tiny dots disappear. Thin lines snap. Fine shading blends into noise.

A good file keeps only what thread can handle.

Strengthening Weak Areas

Edges must hold tension.

Weak shapes fray after washing. Strong shapes last longer.

Digitizers adjust thickness to protect durability.

Simplifying Complex Shapes

Crowded art looks nice on a screen. It looks messy in thread.

Clean shapes read better from a distance. Embroidery is meant to be seen, not studied with a microscope.

Choosing the Right Stitch Style

Each part of a design needs a stitch plan.

Running Stitches for Fine Detail

Running stitches are light. They trace small parts.

They must be used with care. Too much tension breaks them.

Satin Stitches for Borders

Satin stitches create shine.

They work well for text and edges. The angle must match the shape.

Wrong angles twist the thread.

Fill Stitches for Large Areas

Fill stitches cover space.

They must be balanced. Too dense feels stiff. Too loose looks empty.

Experts adjust density for each fabric.

Matching the File to the Fabric

Fabric changes everything.

A file that works on cotton may fail on nylon.

Soft Fabric Behavior

Soft cloth stretches.

The file must allow movement. Tight stitches cause puckers.

Heavy Fabric Resistance

Thick cloth fights the needle.

The file must reduce stress. Balanced spacing protects the fabric.

At Embroidery Digitizing Services in USA - Digitizing Buddy, fabric type is always checked before final output. This step prevents surprises during production.

The Role of Underlay in File Prep

Underlay is hidden stitching under the top layer.

Most people never see it. It is still critical.

Why Underlay Exists

Underlay locks fabric.

It builds a base. Top stitches sit on that base.

Without underlay, stitches sink and shift.

Types of Underlay

Edge underlay supports borders.

Center underlay supports fills.

Zigzag underlay adds strength.

A smart file mixes these methods.

Controlling Stitch Direction

Direction changes how light hits the thread.

It also controls fabric tension.

Visual Depth

Changing stitch angle creates shine and shadow.

This adds life to the logo.

Stress Balance

Poor direction pulls fabric unevenly.

Smart direction spreads force evenly.

This keeps the design flat.

File Density and Thread Balance

Density means how close stitches sit together.

Overloaded Density

Too many stitches weaken fabric.

The cloth cannot breathe.

Weak Density

Too few stitches look patchy.

Shapes lose strength.

Good density sits in the middle. It protects both look and durability.

Testing the File Before Production

No expert skips testing.

Screens can lie. Thread tells the truth.

Sample Stitch Runs

A test reveals hidden flaws.

Letters may close. Corners may pull.

Testing shows the real behavior.

Refining After Testing

Files are adjusted after each test.

Angles shift. density changes. Underlay improves.

Testing is not failure. It is proof of care.

At Embroidery Digitizing Services in USA - Digitizing Buddy, test stitching is part of the workflow, not an extra step.

Common File Mistakes Beginners Make

Many errors repeat across new projects.

Too Much Detail

Overcrowded art turns into thread lumps.

Simple designs stitch better.

Ignoring Fabric Type

One file does not fit all materials.

Fabric must guide the plan.

Skipping Cleanup

Dirty files produce dirty stitching.

Prep saves time later.

Organizing Files for Smooth Workflow

Clean file management helps production.

Clear Naming

Files should have clear names.

This prevents mix ups.

Version Control

Save edits as new versions.

Never overwrite the original.

This protects your work.

Backup Copies

Always keep backups.

Files are valuable assets.

The Human Skill Behind the Software

Software is a tool.

Experience guides the tool.

Judgment Over Automation

Auto tools can help.

They cannot replace human eyes.

A trained digitizer sees problems early.

Learning From Past Projects

Each project teaches a lesson.

Experts remember what works.

That memory shapes better files.

Building Trust Through Consistent Quality

Brands rely on embroidery to represent them.

Clean stitching builds trust.

Messy stitching hurts image.

Repeatable Results

A strong workflow creates the same quality every time.

Consistency builds reputation.

Respect for the Client Brand

Every logo carries meaning.

Professionals treat it with care.

This respect builds long partnerships.

Preparing Files Saves Money

Good prep is not just about beauty.

It reduces cost.

Fewer Machine Stops

Clean files break thread less.

Production runs faster.

Less Material Waste

Mistakes waste fabric.

Strong files protect resources.

The Emotional Side of Craft

Embroidery is technical work.

It is also personal.

Each stitch reflects pride.

When a digitizer cares, the result shows it.

Clients feel that care in the final product.

That feeling builds loyalty.

Final Thoughts

Smooth embroidery starts with clean digital prep. It is not luck. It is structure and discipline. Every shape must be tested. Every stitch must have a reason.

When files are built with care, the machine works calmly. The thread flows evenly. The fabric stays strong. The logo looks sharp.

Great embroidery is hidden engineering. The viewer sees beauty. The expert sees planning behind it.

That planning turns digital art into durable stitching. It protects brands. It protects fabric. It protects trust.

And in the end, trust is what keeps clients coming back for work that is done right the first time.

- SEO

- Biografi

- Sanat

- Bilim

- Firma

- Teknoloji

- Eğitim

- Film

- Spor

- Yemek

- Oyun

- Botanik

- Sağlık

- Ev

- Finans

- Kariyer

- Tanıtım

- Diğer

- Eğlence

- Otomotiv

- E-Ticaret

- Spor

- Yazılım

- Haber

- Hobi